Japanese PSE certification

Introduction to PSE Certification in Japan

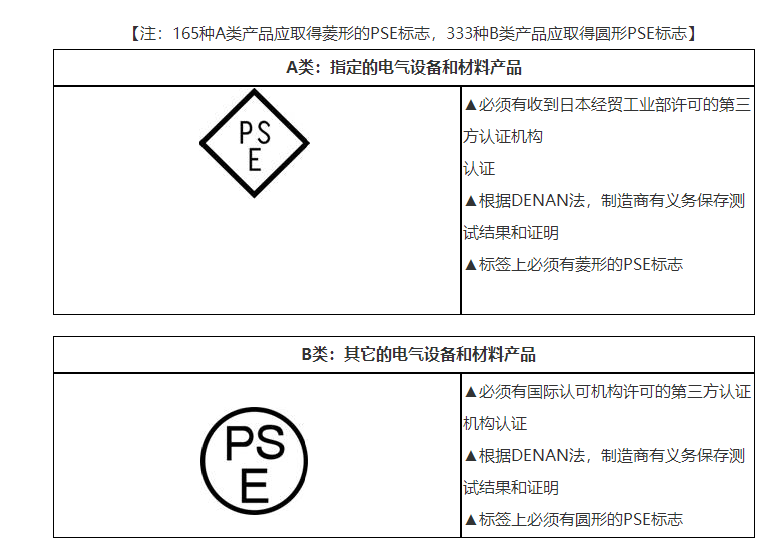

PSE is a mandatory safety certification in Japan. Since April 1, 2001, the Electrical Equipment and Material Control Act (DENTORL) has been officially renamed the Electrical Product Safety Act (DENAN) to prove that motor and electronic products have passed safety standard tests under the Japanese Electrical and Material Safety Act (DENAN Law) or international IEC standards; Among them, 498 products entering the Japanese market must pass safety certification.

Notice of PSE Certification in Japan

Mobile phone chargers are classified as Class A products according to this regulation, and Class A products must be tested by laboratories authorized by the Japanese government and managed by METI. Such laboratories include JQA, LET, UL Apex, and non Japanese laboratories such as UL are also authorized laboratories for this type of product (according to battery chargers and AC adapters). There are currently no laboratories authorized by Japan in China.

Therefore, companies applying for PSE certification should first choose a Japanese authorized laboratory and obtain a testing report issued by the laboratory to prove that the product meets Japan's technical requirements.

Japan has two sets of technical requirements for battery chargers, and applicants can choose any of the following methods:

The first approach is very traditional Japanese technical requirements;

The second approach is to coordinate technical requirements with IEC60950.

It is recommended that domestic applicants choose the second method. Under this method, as both China and Japan are members of IECEE-CB, applicants can first obtain a CB report from CQC in China, and then apply to the above-mentioned laboratory in Japan to transfer the CB report. If the first method is used, the CB report cannot be accepted.

If the product is designed to meet the second method, that is, to comply with the IEC60950 standard, then all safety components of the preliminary circuit, such as capacitors, thermal release devices, etc., must comply with international IEC standards. If the product is designed to meet the first method, that is, to comply with Japanese national standards, then all these safety components of the primary circuit must comply with Japanese national standards. It should be noted that if the first method is chosen, CB reports will not be accepted. It is also not allowed to mix the first and second methods.

Special note: Although Japan is a member of the CB, the CB report can generally only be used as a reference. If CB conducts deviation testing in Japan, CB can directly transfer certification, and the certification cycle is about 3 weeks.

Inspection of PSE certified factories in Japan

PSE will conduct a factory inspection (checking for the presence and suitability of relevant testing instruments) without tracking the inspection. Due to the different cooperation partners of various certification agencies in China, the agencies responsible for factory inspections in China are different. JQA's partner is the China Import and Export Inspection and Quarantine Bureau.